Passive Buildings Techniques

As a “zero emission” science facility that can match just about any energy-efficient building, Princess Elisabeth Antarctica is a living prototype that embodies the principles of passive building.

Passive Solar Gain

Probably the most remarkable properties of Princess Elisabeth Antarctica is that needs no form of heating to keep its occupants warm, as they work and live one of the coldest environments on Earth.

Princess Elisabeth Antarctica maintains its internal temperatures using only incoming sunlight and the heat produced by human beings and the station's electrical appliances.

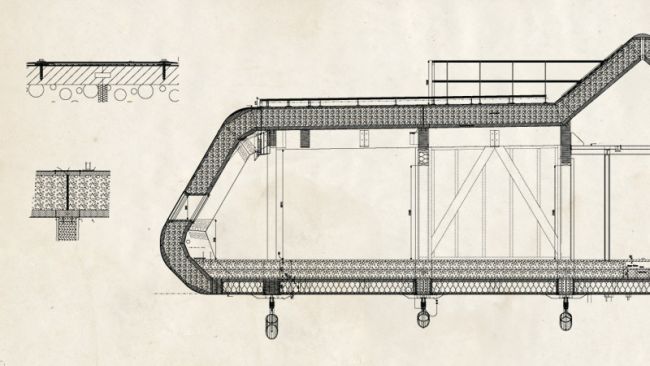

Insulation

Besides the obvious need to shield its occupants from the cold of Antarctica, Princess Elisabeth Antarctic also needs to be air-and-water-tight to achieve optimal energy use and heat transfer.

The nine layers of the station's walls each have their own function; from insulation to blocking water vapour, all contribute to the efficiency of Princess Elisabeth Antarctica as a passive building and a “zero emission” scientific research station.

Nine Different Layers

Stainless Steel (1.5mm)

Stainless steel that covers Princess Elisabeth Antarctica is an extremely resistant material that can withstand the hardships of the weather and prevents water from reaching the wooden interior of the wall panels.

Foam with Closed Cells (3mm)

The station's wall panels are lined with a 4-mm closed-cell polystyrene foam mat, ensureing an air-tight seal around the stainless steel bands that are under the joints between each steel plate that covers the station.

EPDM Silicone Sealant (3mm)

By nature, silicones are highly tensile and tear-resistant materials, and feature resistance to harsh weather, temperature extremes and ultra-violet light. This material is highly suited to the extreme conditions of Antarctica, and used to make Princess Elisabeth Antarctica both air and watertight.

Lamellate Wood (80mm)

At the beginning of the project, the Princess Elisabeth Antarctica team considered the possibility of building the station entirely in metal. This solution, however, would never have been possible to transform into reality as metal expands and contracts under different temperatures, and could have caused the building's outer shell to crack. Wood, which is a poor conductor does not have this problem, and it is also easier to transport from the Antarctic coast to the station's site at Utsteinen nunatak.

Low-Density Polystyrene Charged with Graphite (400mm)

Polystyrene is extremely lightweight, and therefore ideal when designing the panels of Princess Elisabeth Antarctica. Thanks to its unique structure, it is moisture and water vapour resistant, and is ideal for insulation.

Lamellate Wood (60mm)

Another layer of lamellate wood is placed on the inside of the main insulation layer.

Kraft Paper

In addition to the aluminium vapour barrier that covers the station, the kraft paper in the various wall panels also serves as an extra vapour barrier.

Aluminium Vapour Barrier

The station's aluminium vapour barrier covers the entire station in one single piece; even the tiniest hole could let the cold slip through, which could damage the station's structure.

Woollen Felt

Inspired by the iconic Mongolian yurts, the woolen felt layer of the Princess Elisabeth Antarctica's wall modules adds to the insulation properties of the panels, while further enhancing the existing water vapour barrier.

Ventilation and Heat Exchange

Princess Elisabeth Antarctica's integrated heat exchange and ventilation systems extract the vitiated air (air without much oxygen) and replace it with fresh air.

The role of these systems, however, is not only to prevent the station from turning into a sauna, but also to spread the collected heat over the building, with some areas such as the technical core needing more than others.